Products

and technology

Machining

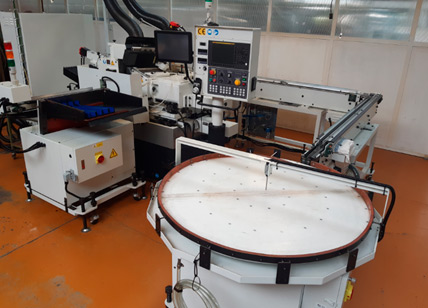

Our specialization is the machining of rotary parts using CNC technology for both the automotive industry and other industrial applications. For this purpose, we use machines equipped with automatic three-metre rod feeders where it is possible to produce parts of ø 350 mm; thanks to sliding headstock machines, we can offer products with a length of more than 200 mm. We also have technology for machining piece blanks using chuck and collet clamping for products up to ø 350 mm. We specialize in the production of high-precision parts utilizing grinders and rolling machines. Our produced parts are accurate to 0.01 mm with roughness to 0.6 Rz max. The machined materials include automatic and carbon steel, brass and cast iron. We use 12 CNC lathes by Goodway, Doosan, Manurhin and ZPS, three non-centered grinders and two rolling machines. As for extra equipment for customization, we utilize pillar drills, threaders, crank and hydraulic presses. We have our own metrological center equipped with a 3D and 2D measuring device, an optical contactless device, microscope, etc.

Our produced parts are accurate to 0.01 mm with roughness to 0.6 Rz max. The machined materials include automatic and carbon steel, brass and cast iron. We use 12 CNC lathes by Goodway, Doosan, Manurhin and ZPS, three non-centered grinders and two rolling machines. As for extra equipment for customization, we utilize pillar drills, threaders, crank and hydraulic presses. We have our own metrological center equipped with a 3D and 2D measuring device, an optical contactless device, microscope, etc.

|

Manurhin K´MX 532 TrendSliding headstock automatic lathe Max. Ø of turning: ø 34 mm |

|

Manurhin K´MX 532 TrendSliding headstock automatic lathe Max. Ø of turning: ø 32 mm |

|

CHIAH CHYUN CB‐32MCNC lathe Max. Ø of turning: ø 32 mm |

|

GOODWAY GLS – 150MCNC lathe Max. Ø of turning: ø 420 mm |

|

Doosan Puma ST32GSliding headstock automatic lathe Max. Ø of drilling: ø 32 mm |

|

Doosan Lynx 2100Max. Ø of turning: ø 350 mm |

|

Doosan Lynx 2100LMax. Ø of drilling: ø 350 mm |

|

Doosan Lynx 2100 LMSAMax. Ø of turning: Ø 350 mm |

|

SPR 63M CNCrevolving lathe Max. Ø of turning: ø 350 mm |

|

Palmary FCL – 18‐4Centerless grinder No. of controled CNC axis: 4 |

|

FEDEK STM‐326(automatic bar‐feeder) Length of rod: 3000 mm |

|

IEMCA BOSS 338‐HD(automatic rod‐feeder) Length of rod: 3000 mm |

|

IEMCA BOSS 552/32(automatic rod‐feeder) Length of rod: 3000 mm |